Product +

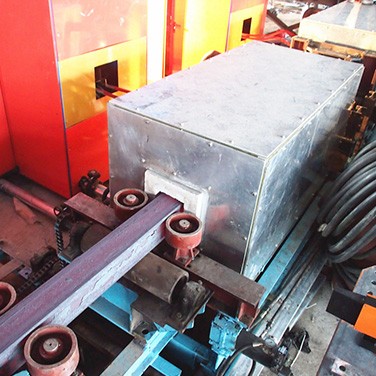

Billet Heating Furnace

- Heating type: MF Induction

- Heatable material: Steel billet

- Heating temperature: 200-1300 degrees

- Heating speed: According to the request

Video:

Application:

The billet reheating furnace is mainly used for reheating the billet before forging or rolling. After the billet is pulled out from the continuous casting machine, the surface temperature is 750 ~ 850℃, internal temperature 950 ~ 1000℃, 1/3 of the interior of the billet does not need to be reheated.

Select different oscillation frequencies according to different billet cross-section sizes, you can get the best heating efficiency.

Product Features:

- 1. Simple operation, flexible feeding and discharging, and a high degree of automation.

- 2. Fast heating speed, high efficiency, less oxide scale

- 3. The heating speed and temperature of the workpiece can be accurately controlled.

- 4. Inductors can be made according to customer requirements, and the maintenance cost is low;

- 5. Energy-saving design, low energy consumption, high efficiency, lower production cost than coal burning, oil, etc.;

- 6. Meet the requirements of environmental protection, low pollution, and small occupied area.

- 7. No need to install, plug and play. No need to preheat, start heating when starting up.

Specification:

| Specification and Technical Parameter |

||||

| Model |

MF Power |

Input Voltage |

DC Current |

MF Frequency |

| KGPS-400 |

400kw |

380V |

800A |

1KHZ |

| KGPS-500 |

500kw |

380V |

1000A |

1KHZ |

| KGPS-750 |

750kw |

380V, 660V |

1500A, 850A |

0.8KHZ |

| KGPS 1000 |

1000kw |

380V, 660V |

2000A, 1140A |

0.8KHZ |

| KGPS-1500 |

1500kw |

380V, 660V |

3000A, 1700A |

0.5KHZ |

| KGPS-2000 |

2000kw |

660V, 1250V |

2273A, 1212A |

0.5KHZ |

| KGPS-2500 |

2500kw |

660V, 1250V |

2840A, 1515A |

0.5KHZ |

| KGPS-3500 |

3000kw |

660V, 1250V |

4000A, 2100A |

0.5KHZ |