Product +

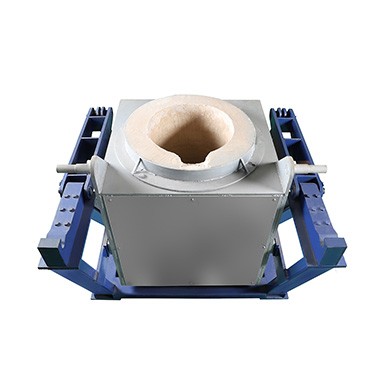

Stainless Steel Induction Melting Furnace

- Melting Body Material: Aluminum Shell, Steel Shell

- Capacity: 0.1T-15T

- Melting Time: 40mins-60mins

- Material Acceptable: Stainless Steel, Steel

- Tilt Type: Hydraulic

- Configuration: Melting Body, Control Cabinet

Video:

Application:

Mainly used for stainless steel scrap, and steel scrap melting. The Medium Frequency Stainless Steel Induction Melting Furnace is designed to meet the requirement of weakly magnetic materials, to improve the resonant part of the power supply, and to meet the demand for constant power output for melting weak magnetic materials.

The stainless steel furnace has a wide range of applications across various industries thanks to its excellent heat resistance, durability, and corrosion-resistant properties. Some common applications of the stainless steel furnace include:

Metallurgical Industry: Stainless steel furnaces are extensively used in the metallurgical industry for processes such as smelting, refining, and heat treatment of metals. They provide a controlled environment with high-temperature capabilities, making them suitable for melting and shaping different types of metals, including steel, aluminum, copper, and alloys.

Heat Treatment: Stainless steel furnaces are commonly employed in heat treatment processes such as annealing, tempering, quenching, and solution treatment. These processes aim to modify the properties of metals by subjecting them to specific heating and cooling cycles, and stainless steel furnaces provide the necessary temperature uniformity and controlled atmosphere required for precise heat treatment.

Foundries: Foundries utilize stainless steel furnaces for the melting and casting of metals. Stainless steel is often used as a crucible material for its high melting point and resistance to chemical reactions, making it suitable for the production of alloys and castings.

Product Features:

- 1. Various models, capacity 0.5T-5T. The Medium Frequency Stainless Steel Induction Melting Furnace mainly consists of a furnace body and control cabinet. Simple installation, only need to contact the electricity and water.

- 2. The melting speed is fast, 30-100 minutes/pot

- 3. The installation of the Medium Frequency Stainless Steel Induction Melting Furnace is simple, just need to connect to electricity and water to use, so no need for installation.

- 4. According to customer requirements increase the melting control system, accurate control of the melting process, and display alloy composition.

- 5. The device has a self-test function, and real-time detection of water temperature, water pressure, over-current, over-voltage, and lack of phase fault information.

- 6. The electrical cabinet modular installation, easy maintenance, less easy broken parts. The separate machine type is mainly used for worse conditions such as dirty working environments, high temperatures, and corrosiveness.

- 7. Constant power output. It can adjust the power of the heating and heat preservation process, which is beneficial to improve product quality and simplify worker operation;

Specification:

| Specification and Technical Parameter |

|||||

| Model |

Power |

Input Voltage |

MF voltage |

Associated Transformer |

MF Frequency |

| 0.1T |

100kw |

3×380v |

750v |

125 |

2000Hz |

| 0.25T |

200kw |

3×380v |

750v |

250 |

2000Hz |

| 0.5T |

400kw |

3×380v |

1500v |

500 |

1500Hz |

| 1T |

850kw |

3×660v |

2400v |

900 |

1000Hz |

| 1.5T |

1000kw |

3×660v |

2500v |

1250 |

1000Hz |

| 2T |

1500kw |

3×660v |

2500v |

1600 |

800Hz |

| 5T |

3000KW |

6×950v |

3400V |

3300 |

800Hz |

| 10T |

6000kw |

6×1250v |

3700V |

7200 |

500Hz |

| 15T |

10000KW |

6×1250v |

4000V |

12500 |

300Hz |