Product +

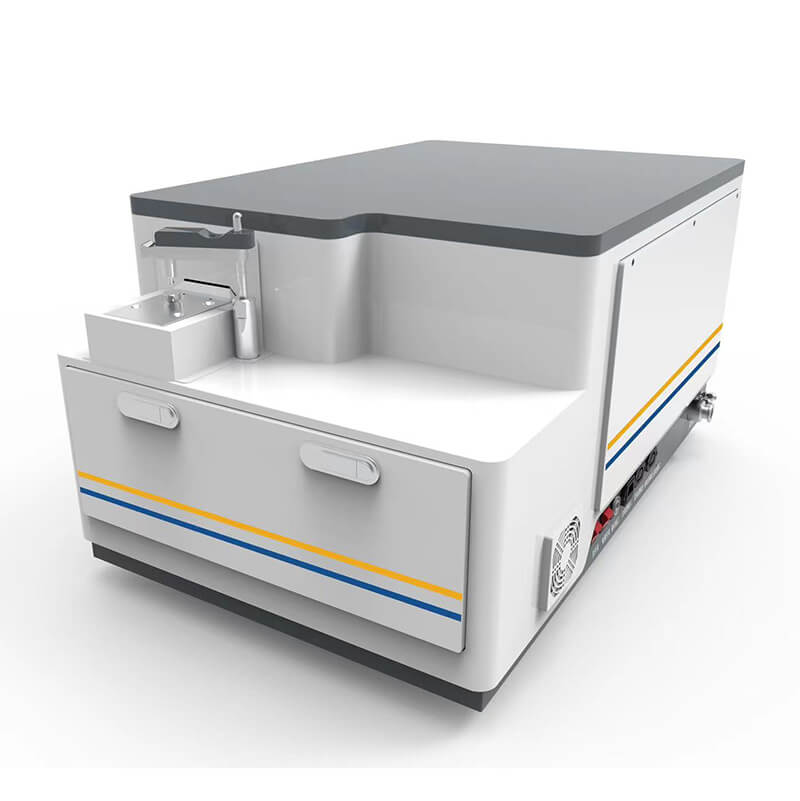

SDB810 Desktop Foundry-Master Pro

- Weight: about 60kg;

- Power Consumption: 1.0kW;

- Vacuum Requirement: 5~12 Pa;

- Argon Module: Analysis flow 4L/min; standby flow 0.1L/min.

Video:

Application:

The desktop foundry-master pro consists of four parts: excitation module, optical path system, CCD detection system, and analysis software. When the instrument is working, under the protection of the chlorine environment, the high-voltage discharge generated by the excitation light source transfers energy to the metal material, causing the metal material to change from solid to gaseous. The outer electrons of the atoms in the metal vapor jump from the ground state to the excited state. The atoms in the excited state are unstable. When the outer electrons return from the excited state to the ground state, energy is released in the form of light. Different elements emit light of different wavelengths. The full spectrum curve is collected through the optical system and CCD detector. The spectrum is decoded by the analysis software. The presence of a certain element is confirmed based on the wavelength of the light. The content of this element is determined based on the intensity of the wavelength.

Desktop foundry-master pros are mainly used to measure alloy element composition and impurity element content in metal materials. They are widely used in furnace inspection, incoming material inspection, quality control and factory inspection in metallurgy, casting, machining and other industries.

The measurement accuracy of the optical emission spectrometer is much higher than the national standard. Since its launch on the market, it has accumulated rich application experience and has been recognized by many well-known customers.

Product Features:

Optical Structure: Adopts Paschen-Runge structure and Rowland circle device to reduce the impact of stress release caused by changes in ambient temperature and vacuum degree of the instrument, and improve instrument accuracy and stability.

Optical Focal Length: Grating radius 400mm, the longer focal length provides excellent resolution for the instrument.

Spectral Line Range: Detectable wavelength range (120 ~ 800)nm, can analyze elements including N, Li, Na, K and other conventional elements.

Meet the requirements for test elements of various substrate materials.

Incident Slit: The slit width is 12μm. The fine incident slit effectively filters out unnecessary stray light, avoids excessive saturation of the detector’s received light intensity, and reduces light intensity interference between elements.

Light Source Lens: It adopts quartz glass material MgF2 transition layer to ensure that C, S, P, N and other ultraviolet wavelengths transmit the strongest light intensity, making ultraviolet short-wavelength

measurement results more reliable.

Detector: CCD detector is used, with up to 16 CCDs installed. It adopts an up-and-down staggered layout with no gaps between different wavelengths, making the light

The spectral wavelengths become a whole, achieving full spectrum coverage to meet customers' needs for multi-element testing.

Concave grating: 2400gr/mm, reciprocal of dispersion rate: 0.47nm/mm (level 1), concave grating can reduce absorption phenomenon, only grating exists

There is no light loss due to primary reflection from the surface, and there is no color difference, which improves the vacuum ultraviolet spectrum effect.

Analysis time: It depends on the type of sample. Generally, an analysis takes less than 40 seconds.

Excitation light source: Digital excitation light source with adjustable excitation conditions to meet the analysis needs of different materials.

Metering method: V-F method

Control system: FPGA technology is used to control the working status of the instrument.

Size: 890*560*515 mm

Excitation electrode: High-purity tungsten electrode is used. High-purity tungsten electrode has the advantages of high strength, corrosion resistance, and high temperature oxidation resistance, which reduces the impact of instrument parameters on test data during use of the instrument.

Instrument weight: about 60kg;

Power consumption: 1.0kW;

Vacuum requirement: 5~12Pa;

Argon module: analysis flow 4L/min; standby flow 0.1L/min.

Specification:

Excellent Argon-saving Technology: Ensuring the reduction of customers’ daily argon demand and reducing enterprise usage costs. Intelligent and advanced gas circuit monitoring: Before excitation, the monitoring system ensures that the sample clamp, sample and spark stage form a loop to ensure that the spark chamber is sealed and air-tight. Ensure that the surface flatness of the sample meets the requirements. After excitation, pulsed argon gas purge improves the dust removal effect and ensures the short-term and long-term stability of the instrument.

Operating System: The use of brand-name computers is more reliable, and the operating software system independently developed by the company is installed. The unique calculation algorithm combined with the excellent hardware system greatly improves the performance of the instrument.